Issue Resolution

Issue Resolution: Solving Problems Permanently

The CAEDENCE Problem-Solving and Issue Resolution Approach

Background

When problems intensify, the customer applies pressure and emotions run high. Business, quality, and engineering leaders need to solve problems fast and ensure their customers have a favorable experience in the process. Whether you’re in the role of supplier or customer, you know these situations are not fun.

CAEDENCE has developed an issue resolution (and prevention) methodology called Visual 8D™ that will transform the effectiveness of your workforce and dramatically improve your customers’ experience. Our method instills the needed problem-solving skills and tools to be able to tackle any business or technical issue. CAEDENCE’s method ensures that your teams are thinking clearly, executing, and communicating flawlessly.

Our Visual 8D™ approach is built on what we’ve learned first-hand over decades leading successful real-world issue resolution teams in the toughest circumstances. We’ve identified 6 key behaviors that can undermine your team’s ability to solve problems and demonstrated exactly what to differently to avoid those traps. Our modern problem-solving toolkit (Visual 8D™) leverages the best of industry-proven methodologies while facilitating the critical thinking and crystal-clear internal & customer-facing communication essential to maintain customer and stakeholder confidence through the life of an issue (something that is, painfully, absent from traditional techniques).

What is Issue Resolution?

What does “issue resolution” mean? Issue resolution (a.k.a. “Crisis Management”, “Problem Resolution”, “Problem-Solving”, and “Emergency Response Management”) is the process for identifying and addressing events or conditions that have already occurred, are occurring, or are likely to occur which have a potential negative impact on a business.

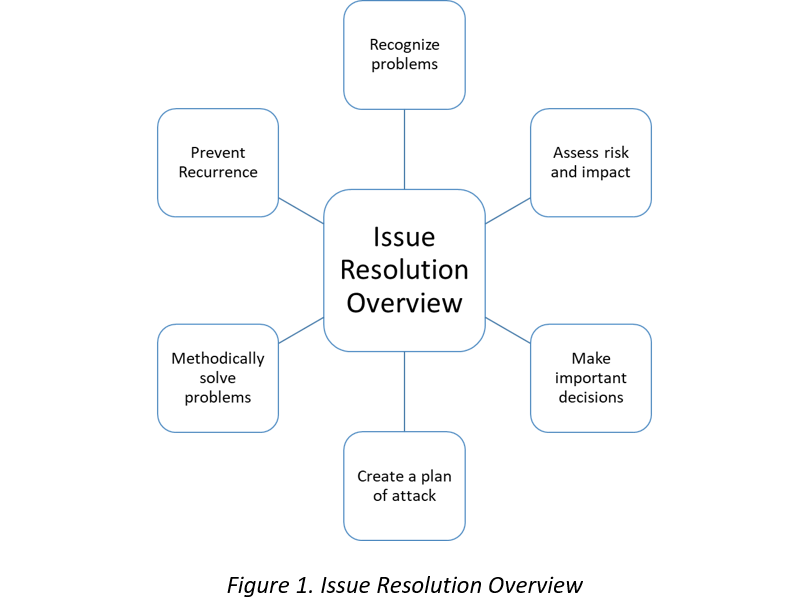

Issue Resolution encompasses the ability to (see Figure 1):

- recognize problems and potential problems

- assess risk and impact

- create a plan of attack

- solve problems methodically

- make important decisions

- uncover systemic breakdowns to eliminate future recurrence (prevention).

What types of business and technical issues are in scope? What are examples of the areas where issue resolution can be applied?

CAEDENCE resolves the biggest pain points in organizations of all sizes. We address the issues that block companies from meeting their highest priority objectives in (see Figure 2):

- Customer Experience

- quality issues / escalations

- root cause analysis

- customer scorecard deficiencies

- Operational Excellence

- project execution

- manufacturing & yield

- internal quality issues

- Product Development

- new product development

- new product introduction

- engineering / technical challenges

(Note: IT and call center problems are out of scope.)

Why is Issue Resolution Important?

Achieving the Required Outcome for the Business

Companies strive to improve their ability to consistently and effectively resolve the most pressing customer- and execution-related issues. Being able to resolve issues effectively means satisfied customers and operational efficiencies leading to growth and improved financial results.

Ability to Execute the Problem-Solving Steps

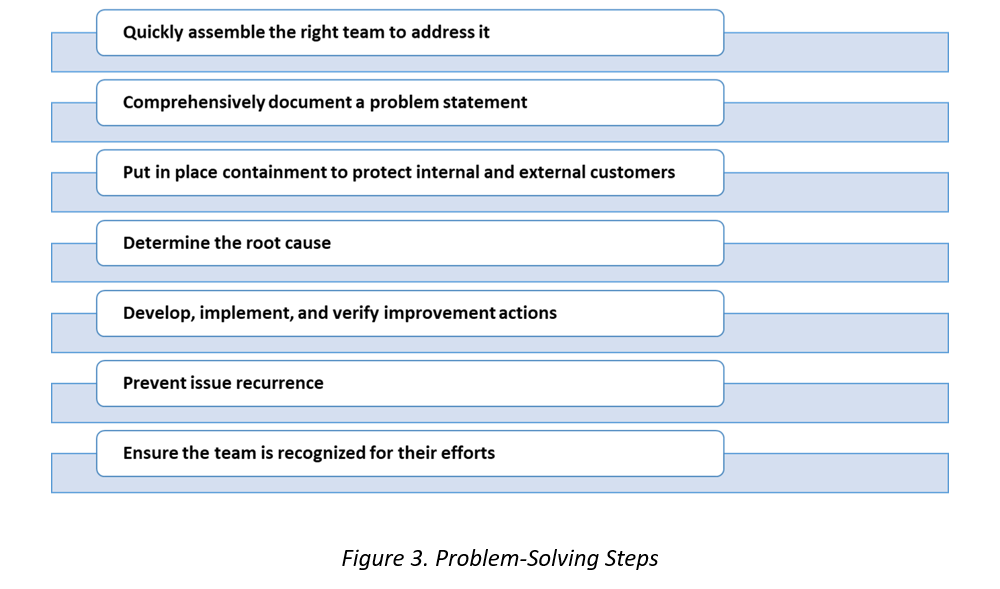

Demonstrating issue resolution skills means that when an issue occurs, your company is able to (see Figure 3):

- Quickly assemble the right team to address it

- Comprehensively document an accurate problem statement

- Put containment in place to protect internal and external customers

- Determine the root cause(s)

- Develop, implement, and verify improvement actions

- Prevent issue recurrence

- Ensure the team is recognized for their efforts

Managing the End Customer

Issue resolution directly impacts customer experience and satisfaction. Customers expect immediate responses to issues. Therefore, your team must act with urgency and effectively manage to tight timelines. Customers expect accurate responses, too. Your team needs to be taking the right actions on the important aspects of the issue. Customers expect to be kept in the loop - if they’re not updated, they’ll assume you’re not committed to resolving their issue. Therefore, understanding and managing the flow of information (i.e., the storyline) during the issue resolution process is essential.

Without crisp management of those expectations, your customer will rapidly lose confidence and may take over control of the situation from you. Once the customer is driving, the amount of work skyrockets as they push your team to explore their (often extraneous) theories and demand frequent (often daily) update meetings that distract your team from the actual problem-solving work. Being able to calm the customer, clarify the storyline, and control the outcome is essential to success.

What can go wrong when solving problems?

The Problem within Most Companies

Problem-solving is fundamental to the engineering and business skill set. Yet, time and again, our team is called in to rescue clients’ teams struggling to effectively execute this core competency. Why? Initially, we assumed that clients’ organizations simply lacked familiarity with structured problem-solving methods, but we quickly realized that this was not the case. These days, anyone who’s been around an industry like automotive, aerospace, or medical devices has been exposed to one or more proven problem-solving approaches like 8D, A3, Six Sigma, or Shainin and their associated toolkits. Even new hires have often studied such methods as undergraduates. So, if everyone is familiar with the best methods and tools, why do so many companies struggle to solve problems?

We see a recurring pattern of 6 behaviors by teams that consistently undermines teams’ ability to resolve issues in a rigorous and timely fashion. These misbehaviors, described below, are the opposites of the recommended behaviors shown in Figure 4.

6 Fundamental Behavioral Issues Inhibiting Effective Problem-Solving – A Synthesis of Real-Life Findings

1. “Not our problem!” – the team is defensive or fails to assume responsibility

An electric vehicle component manufacturer (vendor) received complaints of malfunction from their customer. Their standard returns analysis process found no fault with the device. The manufacturer’s engineering leadership quickly concluded that the issue must be with the customer’s system. It took months of detailed data collection by the customer, followed by a heated senior management meeting, before the manufacturer’s engineering team took seriously the possibility that “maybe it could be us”. The analysis ultimately showed it was indeed the manufacturer’s issue.

When customers report issues, many people react defensively. The fact that some past issues have, indeed, been the customer’s fault (through misuse of the product or a system fault wrongly blamed on the product) leads engineers and managers to (wrongly) presume this is the most likely scenario, delaying a proper response for weeks or months.

A better approach is to be open to the possibility that the customer’s problem could be your fault (however unlikely). Then, take the lead of a combined vendor-customer team and lay out a plan to investigate all possible (vendor and customer) causes. Collaboratively exploring a comprehensive list and evaluating each possible cause encourages exploration of the potential customer causes in parallel with potential vendor causes, without defensiveness. Such collaborations actually strengthen the relationship between the companies. Customers feel respected and well taken care of, and escalations are prevented. By properly scoping the problem to include both customer system and vendor device, causes are likely to be found faster.

2. “Who’s in charge here?” – the team lacks a leader, or the leader doesn’t lead

An industrial manufacturer received an alert about several failed parts. The quality engineer received the parts and loaded information into the tracking database. Days went by. A team hadn’t met. The customer was not informed of status. After 5 days, the customer’s engineering manager called the manufacturer’s quality director demanding an update. The quality director investigated, finding that a team was assembled, but no leader had been named. This happened due to internal communication gaps, people’s tendency to wait for others to jump in and lead, and lack of a formal procedure for assigning leaders.

Teams with an assigned leader fail in a different way - the leader doesn’t lead! Successfully leading an ad hoc issue resolution team requires good project management techniques. This includes assigning relevant tasks to the right owners, maintaining an action list, holding team members accountable to deadlines, leveraging well-structured meetings to drive progress, collecting and synthesizing presentation materials, and ensuring the customer is frequently updated. Sadly, colleagues in engineering and quality functions are not typically taught team leadership or project management skills, nor do they get time to practice outside of emergencies.

Success hinges upon having an unambiguous process to assign a leader on day 1, and making sure that leader understands their function as the customer-facing voice (usually), driver of progress, planning coordinator, and update presentation compiler. Knowing that inexperience, skill gaps, and company culture can doom a team leader, it is imperative that project management skills be developed ahead of time in those who will lead these teams.

3. “Not my job!” – cross-functional team members lack accountability

A semiconductor company was struggling to resolve a longstanding product issue. A team of experts was assembled, but its performance was lacking. Actions weren’t completed on time, and technical work was not rigorous. There was little progress toward identifying the root cause and the customer was becoming increasingly irritated.

In many companies, Subject Matter Experts (SME’s) are primarily involved with technology selection and product development. Customer or production issues are outside of their scope, and are seen as distractions from their primary activities. We often see an appalling lack of commitment by SMEs to issue resolution teams. People come to meetings unprepared. If they’ve brought data at all, it has not been vetted. Action deadlines set by the team leader or customer are flouted.

Rather than viewing issue resolution as an “extra” activity and relying on the goodwill of experts to make time to help, managers should reserve expert capacity in anticipation of issues. Experts’ annual goals should include a section on resolving issues. Building issue resolution into the goals of technical experts changes their view of issues from “distraction” to “core”, increasing focus and commitment.

4. “The academic without the practical.” – teams fail to use best practices or don’t have practical problem-solving training

Teams routinely act and then later rationalize their actions into the problem-solving framework, or they try to apply problem-solving tools without following best practices, resulting in wasted time and worthless documents. We joined a major problem-solving effort with a 100-page 8D (a widely-used problem-solving framework) report and a multi-page Is/Is Not Diagram (a common scoping tool). Unfortunately, none of the information in those tools was being used to drive the team’s investigation. Each problem-solving tool should be deployed based on the specific type of question to be answered. Using tools to simply comply with a system is unhelpful, even counterproductive.

We previously highlighted the that most engineers are familiar with structured problem-solving. However, there is a gulf between “familiarity” and “mastery”. Talent development experts know that guided practice is essential for mastery. After seeing a concept, students must practice, but practice without feedback can reinforce bad habits. Practice with real-time, expert feedback is the best way to master a new skill. Top athletes don’t practice randomly – they have a coach’s guidance. Developing world-class problem-solving skills is no different.

5. “We don’t have time to make a plan!” – teams fail to map out and communicate a plan

An automotive tier was frustrated with their supplier’s inability to resolve a chronic problem. We arrived to find a poorly-organized supplier team operating in a highly reactive mode. The more the team floundered, the more pressure the customer applied. The team’s (97 item!) action list focused on finding answers to customer questions. Alarmingly, none of the actions were tied to a coherent plan to define containment, identify the root cause of the issue, or generate solutions. Engineering was busy running tests, yet they couldn’t articulate the underlying reasons why they were doing them. We insisted that a list of root cause hypotheses be developed and that testing be designed to rule-in or rule-out each idea in order of likelihood. By involving the customer in this planning process, the random questions stopped and the chaos quickly subsided.

We’ve repeatedly joined teams in place for >6 months who: couldn’t articulate their problem statement, had jumped to “solutions” without understanding causes, dove into aimless testing, or ignored containment. These items are fundamental, yet these steps were skipped by experienced people. As mentioned in section 4, knowing a method isn’t the same as

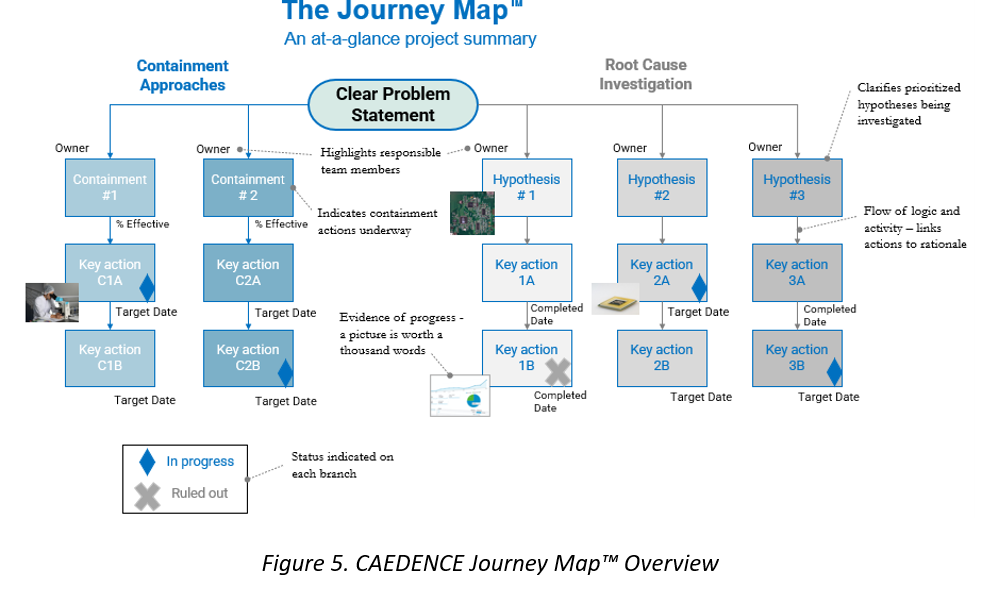

incorporating it into your thinking and daily work. Under stress, teams revert to instinct, sometimes making decisions out of fear not logic. Aligning internal and customer teams around a visual plan is key to success. Having a fishbone diagram and an action list is not the same as having a clear plan. The most important tool in any root cause investigation is what we call the Journey Map™ (which can be thought of as a combination of an annotated fishbone diagram and a sequenced action item list) (see Figure 5).

The Journey Map™ is primarily used to develop and clarify the plan of attack for the team and customer. A well-crafted Journey Map™ shows "you are here" in an unfolding situation. Viewing the Journey Map™, anyone new or peripheral to the team can quickly see where you are, how and why you got there, and what's going to happen next.

The sharing of a plan in visual form clarifies the flow of problem-solving logic, connects sub-actions to their big-picture objectives, and instills confidence in the approach and timing of events. When the activity is complex, the Journey Map™ reduces the risk of people getting lost in the details. It is an excellent tool for periodic customer or management updates.

6. “What do you mean?” – team members struggle with communicating to influence an issue to closure

Weekly customer updates were becoming increasingly tense, and the escalation process had already begun when we came on board. There was a longstanding field issue with a vendor’s component at their heavy equipment customer. The vendor team had been working diligently, but unsuccessfully, to understand the cause. Feeling uncomfortable, the team didn’t share much detail with the customer about what they were doing. Sometimes they presented test results without linking their meaning to the “big picture” of the investigation.

We re-framed the project, clarifying the hypotheses and plans for ruling each one in or out. Drawing on the reserve of technical work that had been done but not presented effectively, we doled out completed work each week, which the customer perceived as a positive inflection in progress. We coached the engineers to frame data in context and ensure the relevant implications to the overall investigation were clear when presenting test results.

When customers aren’t hearing clear, understandable plans, aren’t seeing evidence of regular progress, or don’t understand the significance of new information, they get nervous and begin to “help” by asking increasingly difficult (often tangential) questions. Teams tend to prioritize customer questions for action, subverting their own plans, which leads to activity without progress. This inevitably drives escalation.

Many engineers prefer to focus their attention on technical work, but it is essential to remember that businesses are made up of people, and people are “hard-wired” for stories. Crafting a narrative is essential for maintaining control of update meetings and preventing customers’ “hijacking” the discussion. The ideal narrative is framed by a crisp, purpose-driven agenda - the scope statement crafted uniquely for each update meeting showing the 3-8 specific items that will be discussed. Think of giving the audience “directions” prior to taking them on a journey: starting point, destination, and sights to be visited along the way. Sticking to the agenda, and leveraging it to pull tangential discussion back on track ensures everyone hears the desired message. Further, “Connecting the dots” between context, hypotheses, test results, and implications is essential.

What is the Best Way to Solve a Problem?

The best way to consistently and permanently solve problems includes taking the steps outlined above to correct the 6 undermining team behaviors and implementing a proven, structured problem-solving methodology that stresses clarity of communication.

The CAEDENCE Visual 8D™ problem-solving method reduces problem-solving time and facilitates effective management of the customer experience. This saves money and develops customer loyalty. Leveraging the Visual 8D™ toolkit helps your team to provide stakeholders with quick insights and focuses subsequent information-gathering efforts where they are likely to have the biggest impact. Using Visual 8D™ is fast. The first iteration can be prepared in just a few minutes, guiding the team through the creation of a plan of attack and facilitating their organization of the information the customer will want to know for easy communication. If you have prior experience with traditional Corrective Action Preventive Action (CAPA) methods, you’ll recognize that the customer can quickly lose confidence when a team’s response is unorganized or lacks critical details. Once they begin to lose confidence, things go from bad to worse as the customer starts escalating and intervening more forcefully – driving a reactionary chaos that causes a lot of stress, but generally doesn’t get the team to the root of the issue any faster (if anything, it usually takes much longer in those circumstances).

Following a structured method like Visual 8D™ is an aid to critical thinking, not a substitute for critical thinking! It does not provide answers, it provides a framework for asking the right questions in the right order to uncover the answers. It is a methodology focused on how to think about problems that breaks the tendency to rely on hard-wired assumptions. Logical fallacies and cognitive biases often guide our actions, to our detriment. Humans naturally make assumptions about cause & effect relationships based on experience. However, these shortcuts are frequently incorrect because they ignore subtle differences between the current problem and past situations.

What are the problem-solving steps?

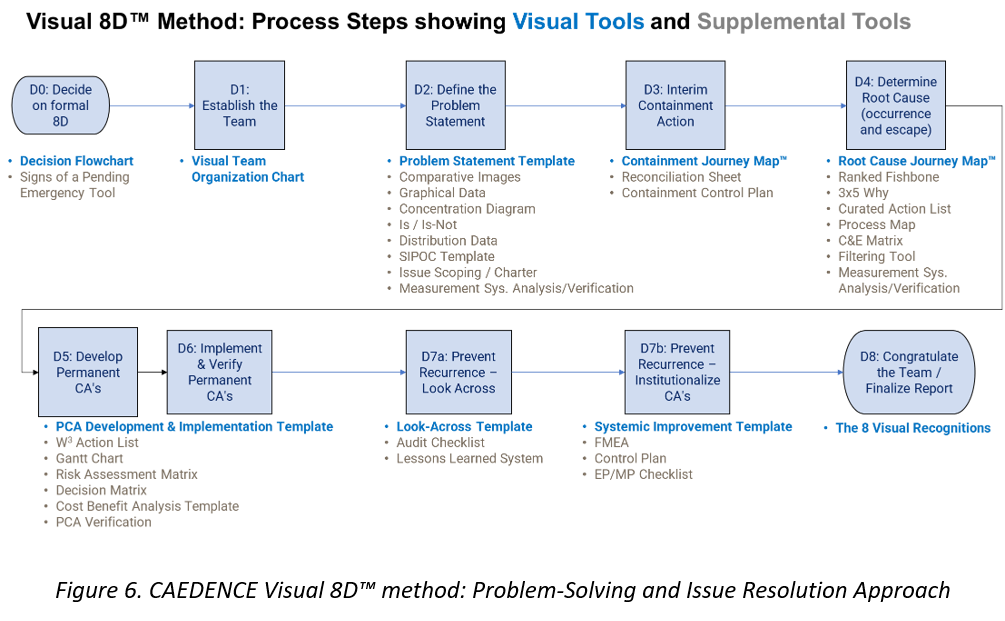

The CAEDENCE Visual 8D™ method is made up of an initial decision matrix (to determine the type of problem-solving method needed) followed by 8 important steps that structure the problem-solving process to achieve success. See Figure 6.

Detailed Step by Step Summary of the Visual 8D™

D0 Criteria for V8D™ – Tool: Decision Matrix

- Determine whether the issue warrants a focused response

D1 Establish the Team – Tool: Visual Team Org Chart

- Ensures a leader is named

- Establishes responsible owners for each focus area

- Defines responsibilities

- Clarifies contact info and escalation paths

- Encourages team commitment

D2 Define the Problem Statement – Tool: Problem Statement Template

- Collects formal and complete information describing the issue

- Quantifies current performance relative to customer expectations

- Does not include any presumed causes or solutions

- Define the scope of the problem or area of investigation

D3 Containment – Tool: Containment Journey Map™ Template

- Protects the customer from issue symptoms before root cause is known

- Guides the team to consider all relevant factors

- Visually clarifies the team’s plans and progress

- Customer communication becomes a confidence-builder

- Confirm the Measurement System:

i. Confirms the issue (and

improvement) can be

measured effectively

ii. Prevents making decisions

with incorrect data

D4 Root Cause Investigation – Tool: Root Cause Journey Map™ Template

- Scoping: Decide where in the supply chain or process to focus

- Prevents ‘boiling the ocean’ and looking too broadly

- Hypothesis generation: structures the root cause investigation focus areas

- Planning: aligns actions for hypothesis rule-in/rule-out

- Considers causes of occurrence and escape

- Ensures thorough consideration of potential contributing factors

- Facilitates communication of plans and progress

D5/D6 Develop & Implement Permanent Corrective Actions – Tool: Action Plan Template

- Encourages broad consideration of potential corrective actions

- Facilitates creation of clear implementation action plan

- Drives relevant documentation review (e.g. FMEA)

- Estimation of corrective action effectiveness

- Drives risk assessment

- Drives cost analysis

- Confirms the improvement

- Uses a crisp action log, not an un-curated list

- Segments actions into focus areas with owners to drive progress

- Verifies corrective action effectiveness

D7a Prevent Recurrence, Look Across – Tool: Look Across Template

- Comprehensive summary of potential ancillary impacts of the issue

- Recommended tactics to assess potential impacts

- Implement actions across all products, processes, and factories

- Deploy improvements also across the supply chain

D7b Prevent Recurrence, Systemic – Tool: Systemic Prevention Template

- Comprehensive summary of potential systemic contributors to the issue

- Recommended tactics to address systemic contributors

- Control the outcomes permanently

- Update all procedures and documents

- Implement solutions for all systemic breakdowns

D8 Congratulate the Team – Tool: Visual Recognition

- Suggests visual means to recognize the successful problem-solving team

Supplementary tools:

- W3 action management template

- Graphical problem definition tools

- Ranked fishbone diagram template

- Is/Is-not template

- Focused Title™ Technique for slides

- Outcome-based agendas

- Narrative Technique™ communication

How to Embed the Problem-Solving Culture

How does the CAEDENCE Visual 8D™ problem-solving method get embedded into the company culture?

A company’s culture will not change overnight, and you won’t move the needle with training alone. It's critical to build knowledge and buy-in across the organization to steadily develop the culture you want to flourish.

Training is typically a single-point-in-time event. It can be effective to drive awareness and provide background in problem-solving techniques, but it alone does not engrain habits. There are many additional enablers necessary for success that must be orchestrated to achieve the desired result for the long-haul.

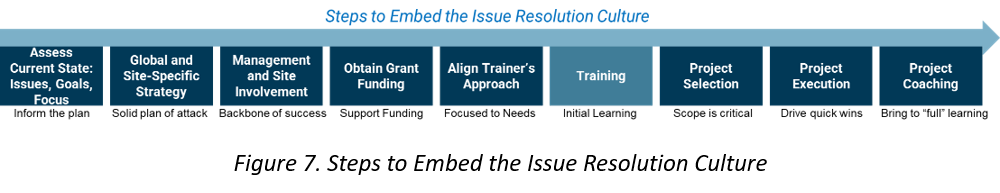

Some of the cultural success enablers include (see Figure 7):

- Defining company objectives by assessing current state performance, understanding where the problem-solving process is breaking down, and customizing an approach for improvement.

- Setting up a management steering team:

- Provides global leadership, strategy, and consistency in approach across the company

- Ensures that each company site’s training, projects, and overall execution are rigorous, recognizing that each site may have different focus areas & needs.

- Creating organizational structure and tracking mechanisms:

- A rollout is managed, not trained. Most efforts fail due to lack of management of the entire effort.

- It is important to show progress, report to management, and celebrate successes including:

- Reviewing project selection criteria, project status, savings delivered

- Scheduling of class participants and coaching

- Identifying and leveraging subject matter experts (SMEs)

- Creating a structure with site steering teams

Additional management techniques to make the culture “stick”:

- Developing KPIs to monitor progress

- Making problem-solving effectiveness a priority for annual plan

- Adding problem solving objectives to individual annual priorities

- Recognizing successes and providing awards

- Documenting the problem-solving processes and tools into the company business management system

- Providing coaches to support project execution

Summary

Deploying an effective issue resolution process and the skills to execute it are critical to any company’s success because they are essential to a positive customer experience. Despite widespread familiarity with proven problem-solving methods and tools, many companies struggle to resolve issues effectively and efficiently.

We've identified a pattern of six behaviors that hold teams back from prompt and rigorous issue resolution and defined tactics to address them. Elements of defensiveness, lack of leadership, lack of accountability, absence of pragmatic best practices, failure to plan, and muddled communication conspire to undermine the effectiveness of structured problem-solving paradigms.

CAEDENCE has developed Visual 8D™, a structured approach and toolkit that guides a team swiftly through the most effective problem-solving steps, enabling them to remain in control of contentious customer situations, drive action, and communicate clearly with stakeholders.

Embedding a problem-solving culture at a company requires management commitment and several control mechanisms. The results will positively impact company bottom line, support growth, and greatly improve customer experience & satisfaction.

How to Contact Us for More Information

Contact us to find out more about how we can embed the CAEDENCE Method into your business.

Major problem or issue that needs resolving quickly? Contact us to see how expert facilitation of your issue could help.

If you have enjoyed this article, please tell us about it – we would really like to get your feedback!